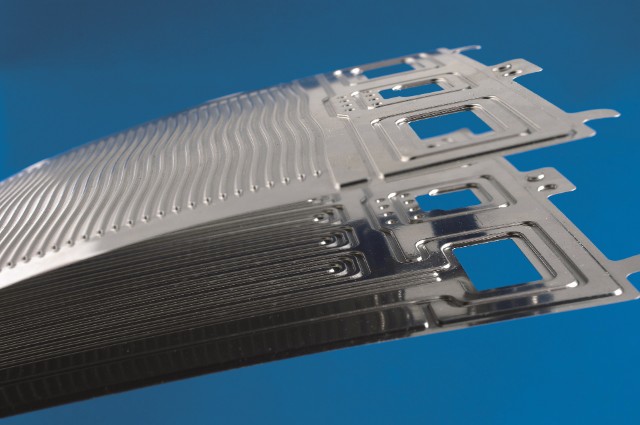

Scientist of the Test Center for Maritime Technologies started operation in a unique three million square meter offshore test area in the German North Sea near the offshore island Helgoland. It offers widespread test applications for marine materials and technologies, not only under water but also for aerial applications (e.g. AUVs & UAVs for inspection and maintenance work). Testing is possible under harsh offshore conditions (sea spray, wind, currents) within different temperate ranges for long time series or short-term tests. Due to the proximity of only three nautical miles to Helgoland short reaction times and a cost-efficient logistic infrastructure can be realized.

Dr. Hanno Schnars, Director of the Test Center for Maritime Technologies: “The location with up to 45 meters depth is ideal for such tests, as the conditions close to the island of Helgoland are representative for the North Sea and similar oceans, like the Atlantic Ocean. The harsh environmental conditions mean a high load for materials and technologies and testing the systems under these environmental conditions is, so to say, the ‘baptism of fire’ for them. If they can cope with these harsh conditions, they succeed everywhere else.”

For industrial partners a range of services can be offered by the Test Center for Maritime Technologies, e.g. planning, engineering, logistics, and performance assessments. Expertise in the marine sector is guaranteed by an interdisciplinary research consortium under the leadership of the Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM together with the German Research Center for Artificial Intelligence (DFKI), the Helmholtz-Zentrum Geesthacht – Centre for Materials and Coastal Research (HZG), the Institute for Chemistry and Biology of the Marine Environment (ICBM) at the University of Oldenburg and Jacobs University Bremen. In addition, the consortium receives scientific support from the Alfred Wegener Institute, Helmholtz Centre for Polar and Marine Research (AWI).

For further information, please visit the website

Fraunhofer Representative Office Japan

Fraunhofer Representative Office Japan