Fraunhofer ILT

Modular Prototype Production with Lasers Enables Faster Gas Turbine Development

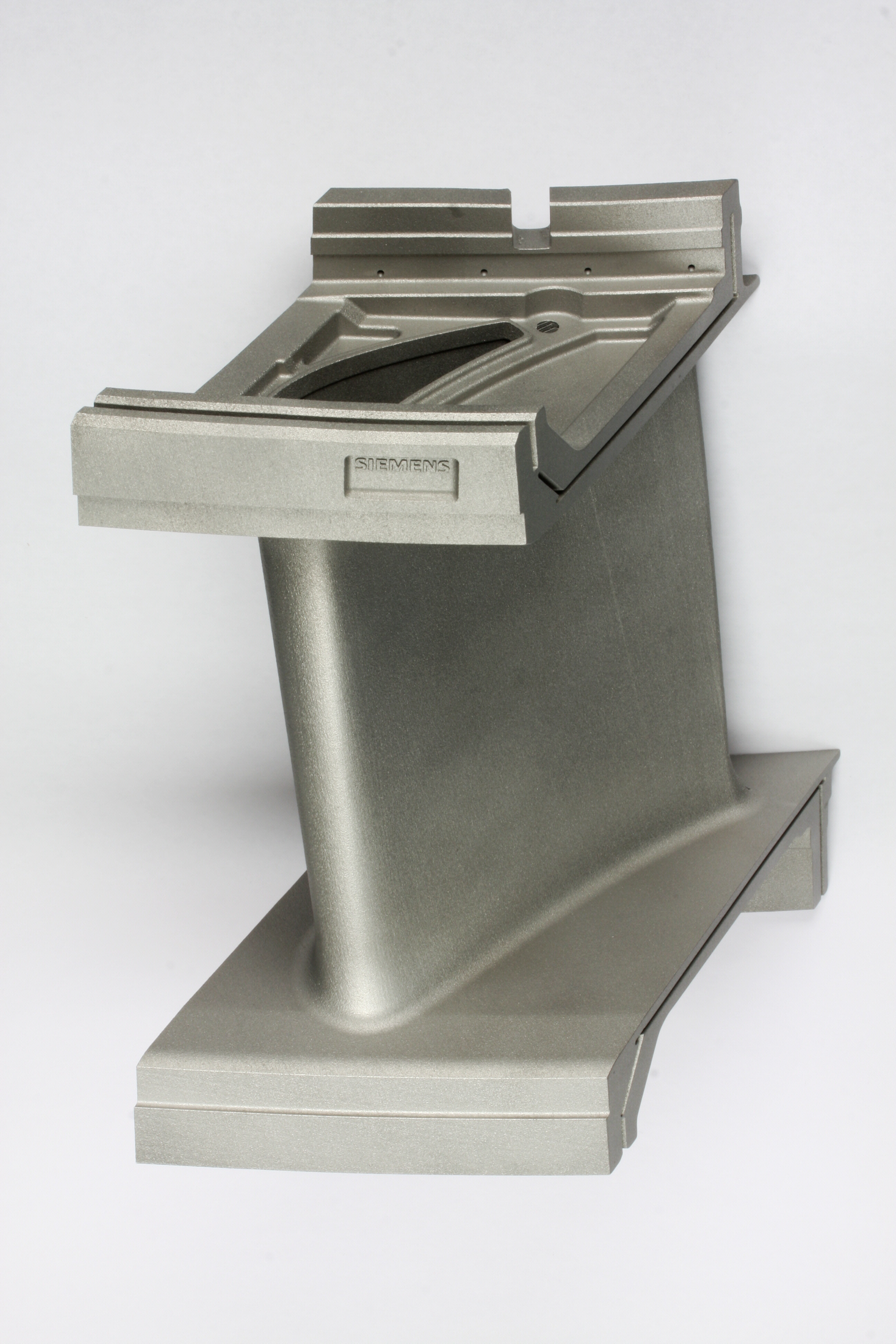

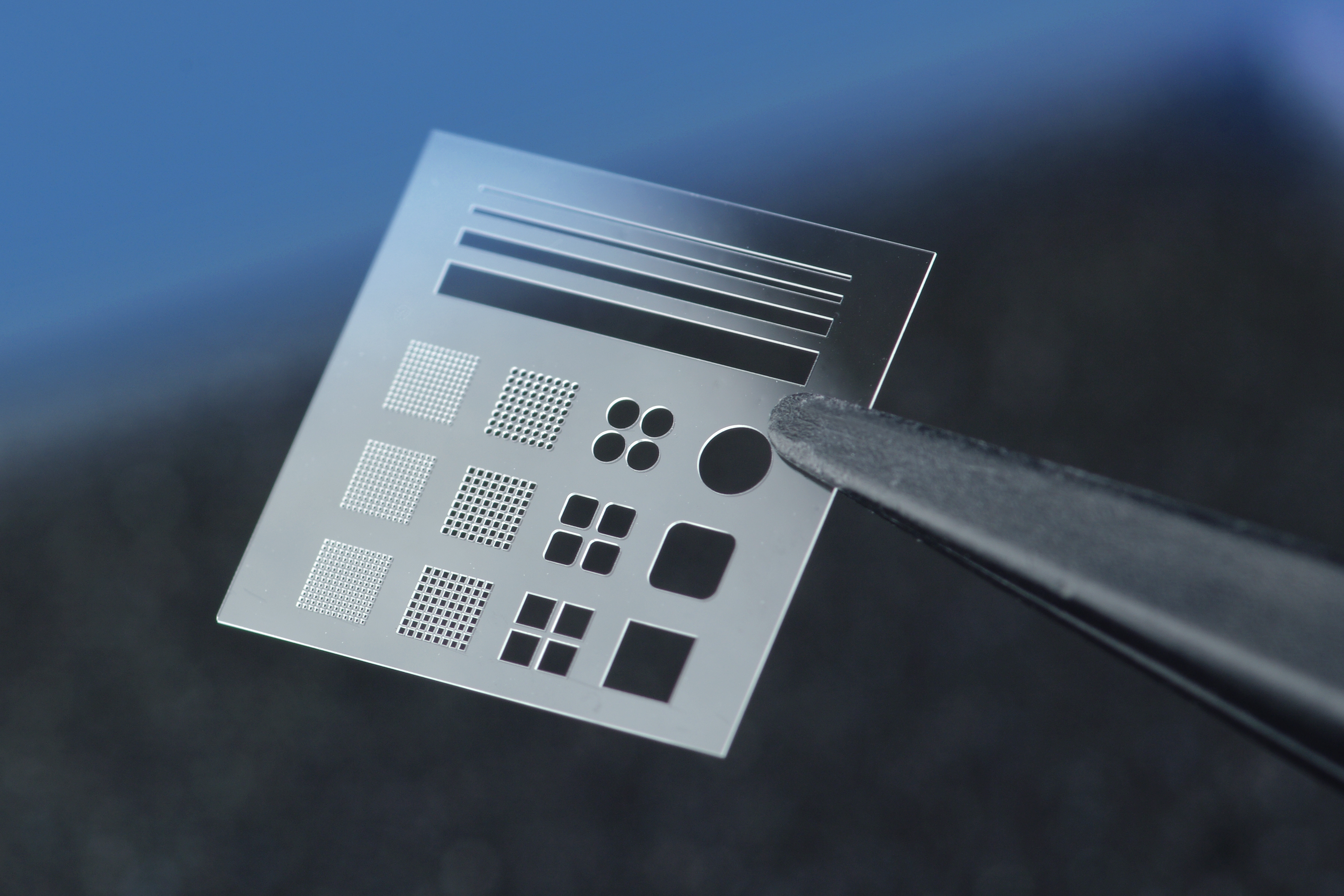

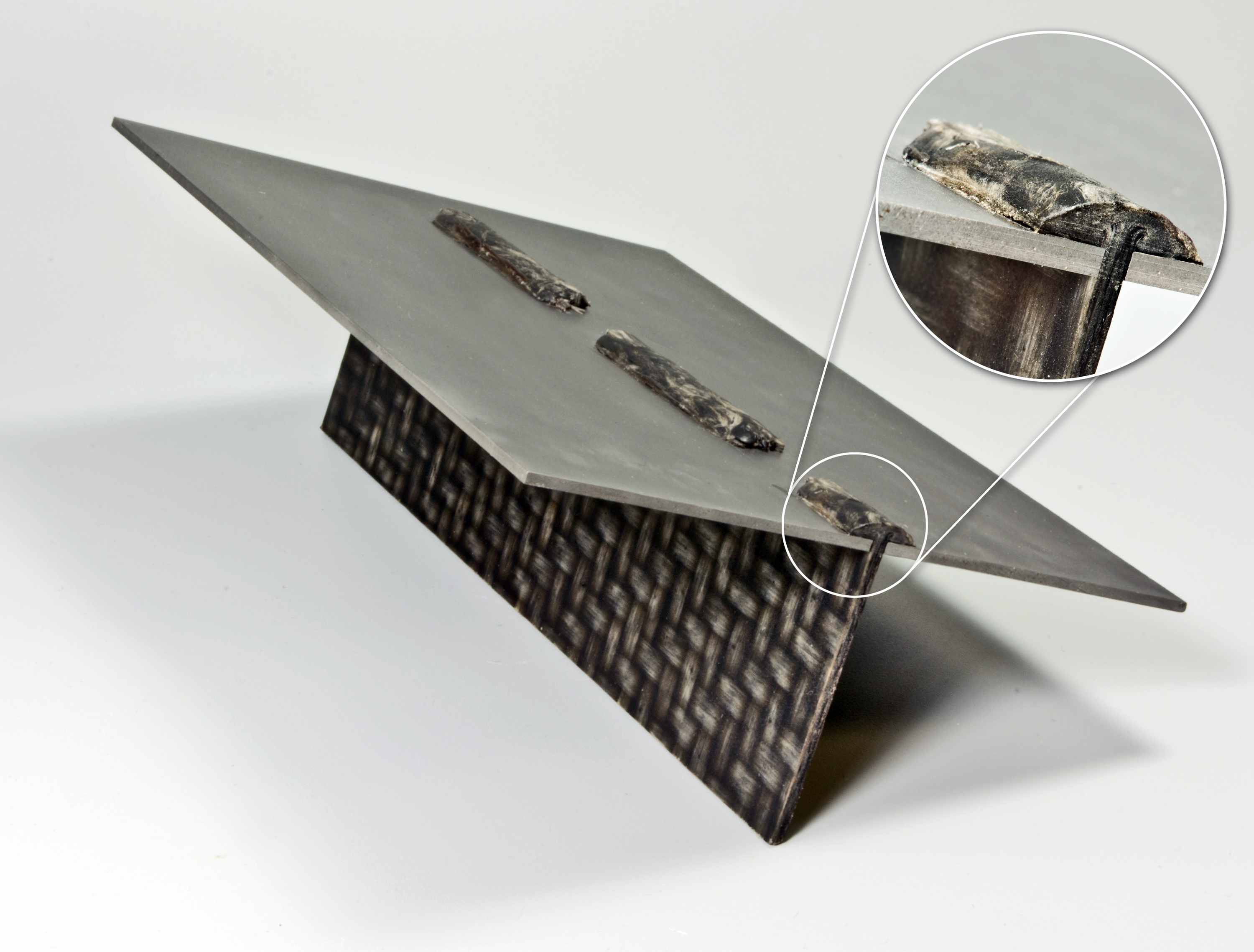

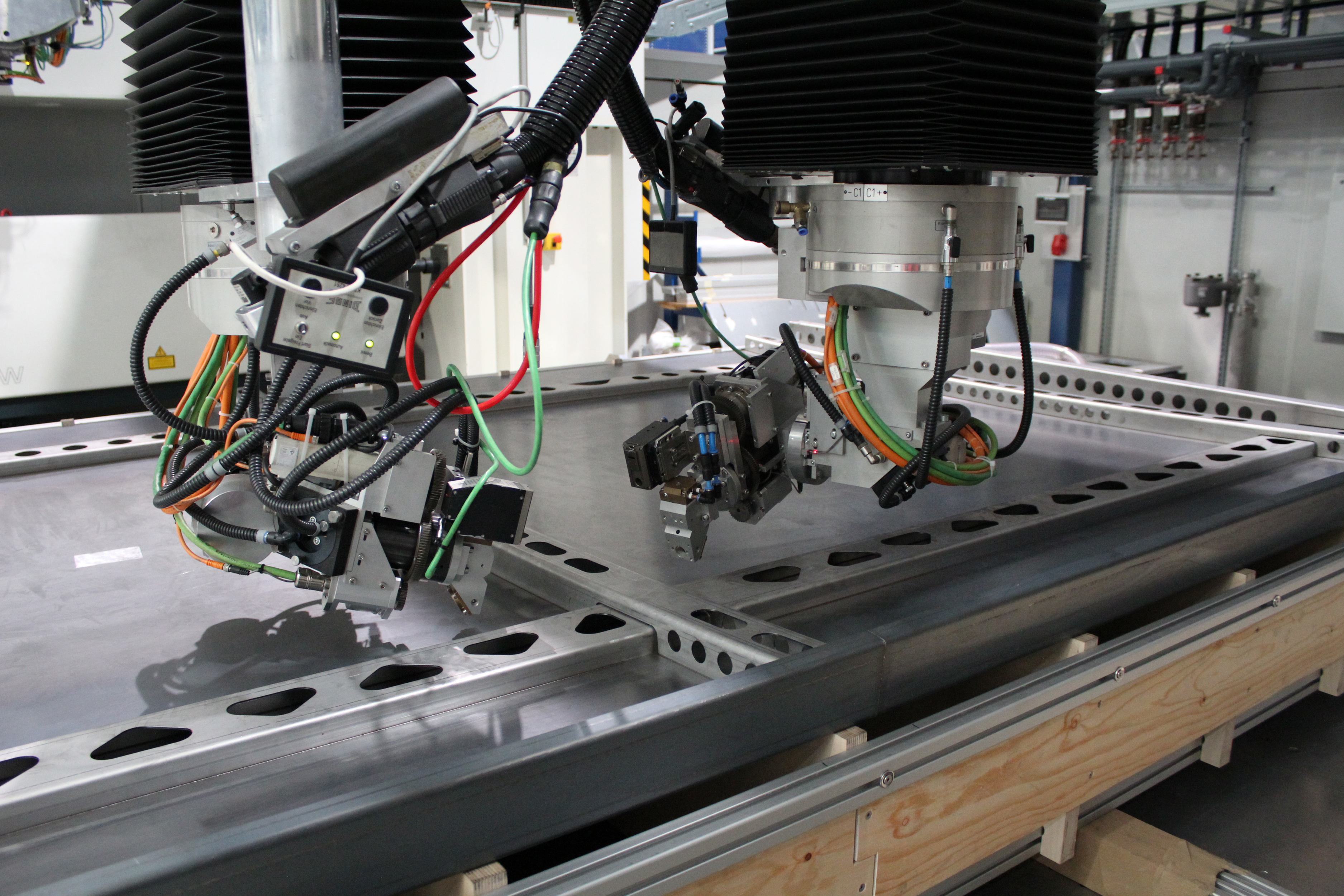

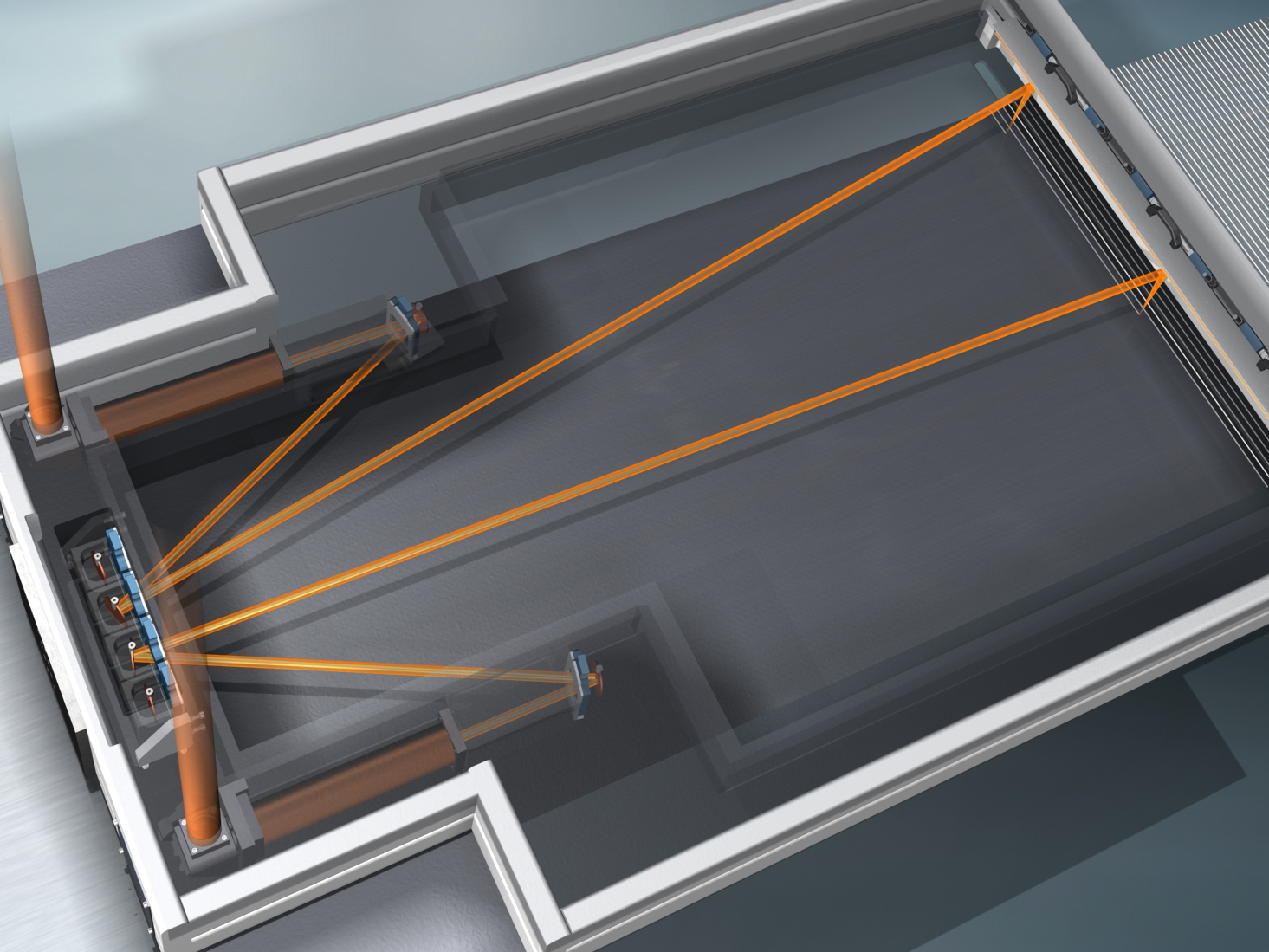

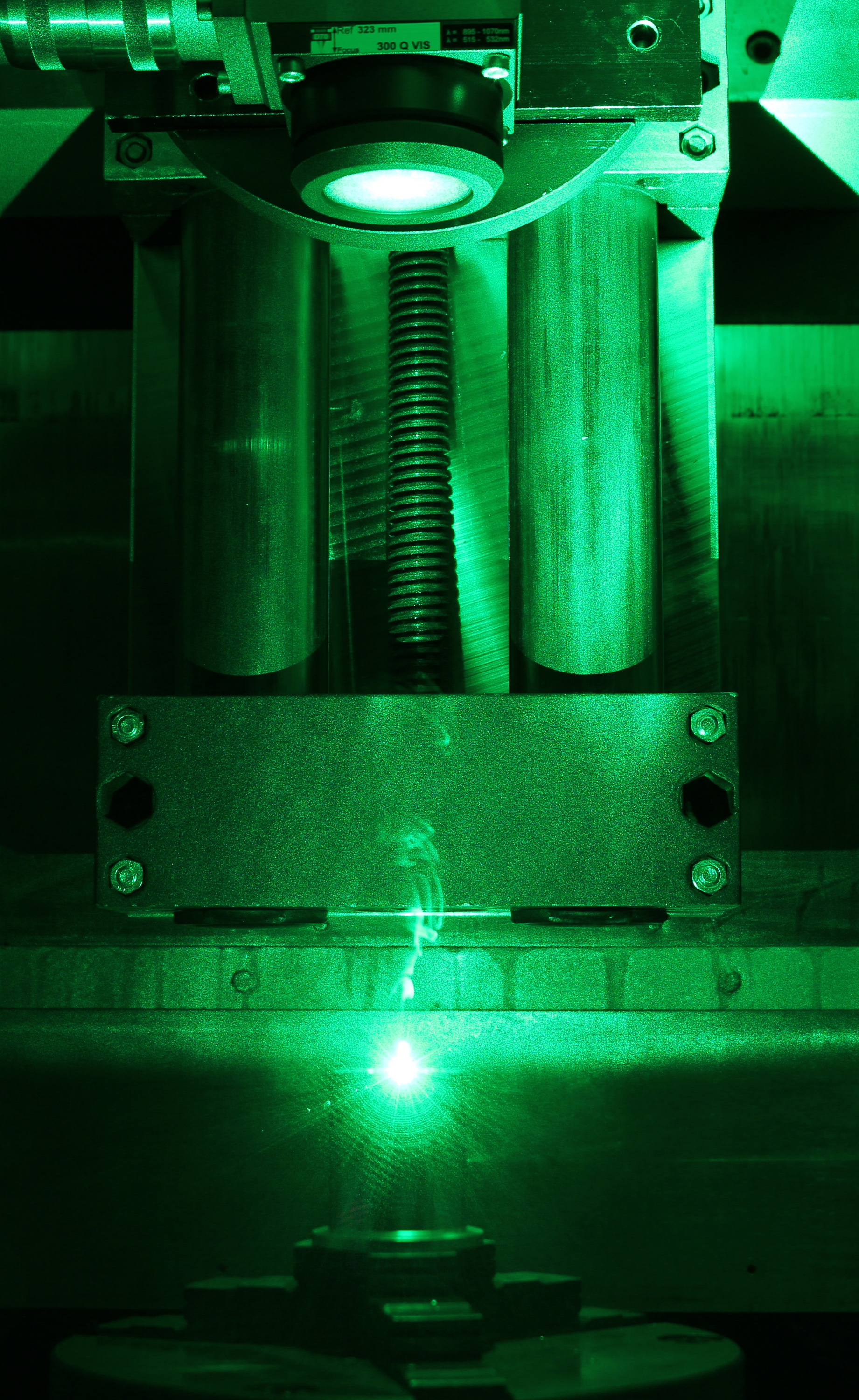

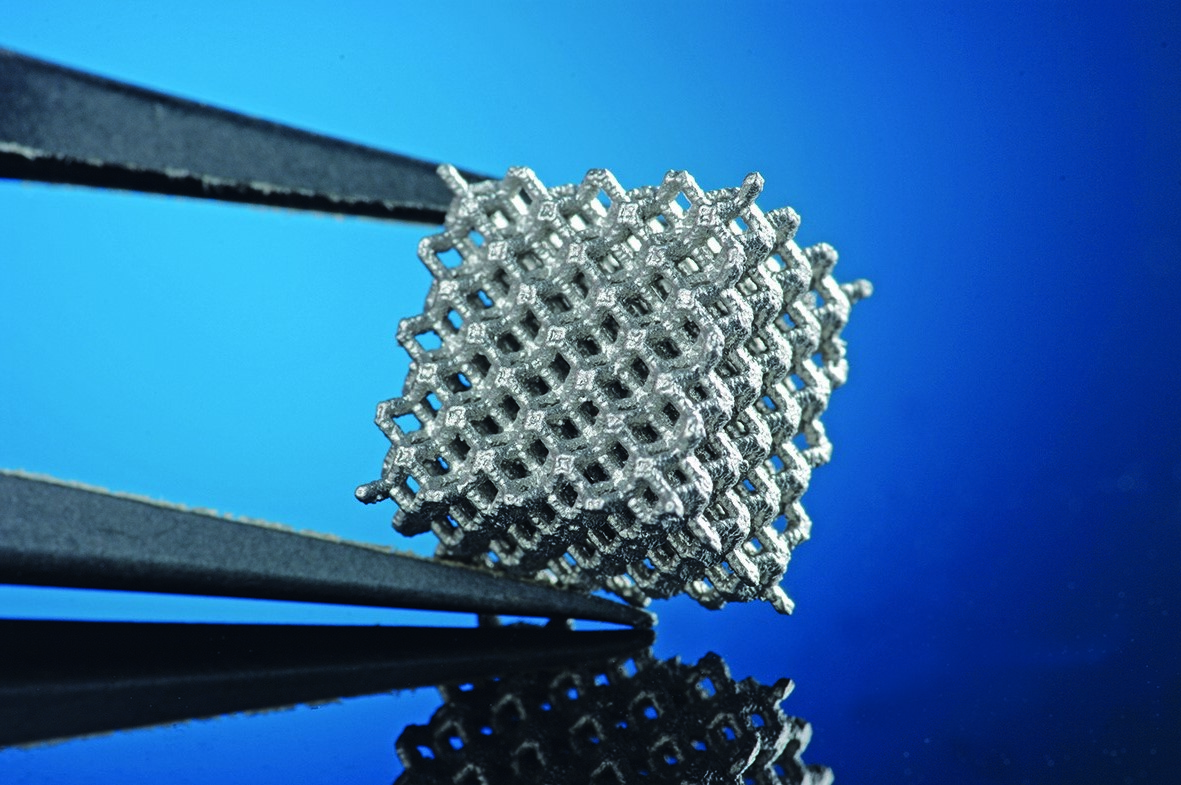

The long lead time of turbine blades and vanes presents a big challenge to the validation of new part designs in engine tests. Conventional vane production through casting is unsuited for the fast iteration cycles required today in the development of hot path components. In a joint project, Siemens and the Fraunhofer Institute for Laser Technology ILT have now developed a faster production process based on selective laser melting (SLM). Components are manufactured in a modular way in the new process chain, resulting in additional benefits.

For more information, please visit the ILT Website

Modular Prototype Production with Lasers Enables Faster Gas Turbine Development

Fraunhofer Representative Office Japan

Fraunhofer Representative Office Japan