Fraunhofer IKTS offers solutions on high-performance screen-print pastes, nanoinks and powders towards the next generation of power electronics and advanced functional elements.

Highlights:

Power electronics is becoming a key technology for a rising number of products and systems due to a global trend to green energy. For increasing local current transport and storage, new low-cost converting equipment is needed. Key challenges facing R&D nowadays are system integration, higher energy density, better heat dissipation, higher robustness and reliability as well as optimized passive components.

High performance thick-film pastes for AlN, Si3N4, and warpage-free LTCC

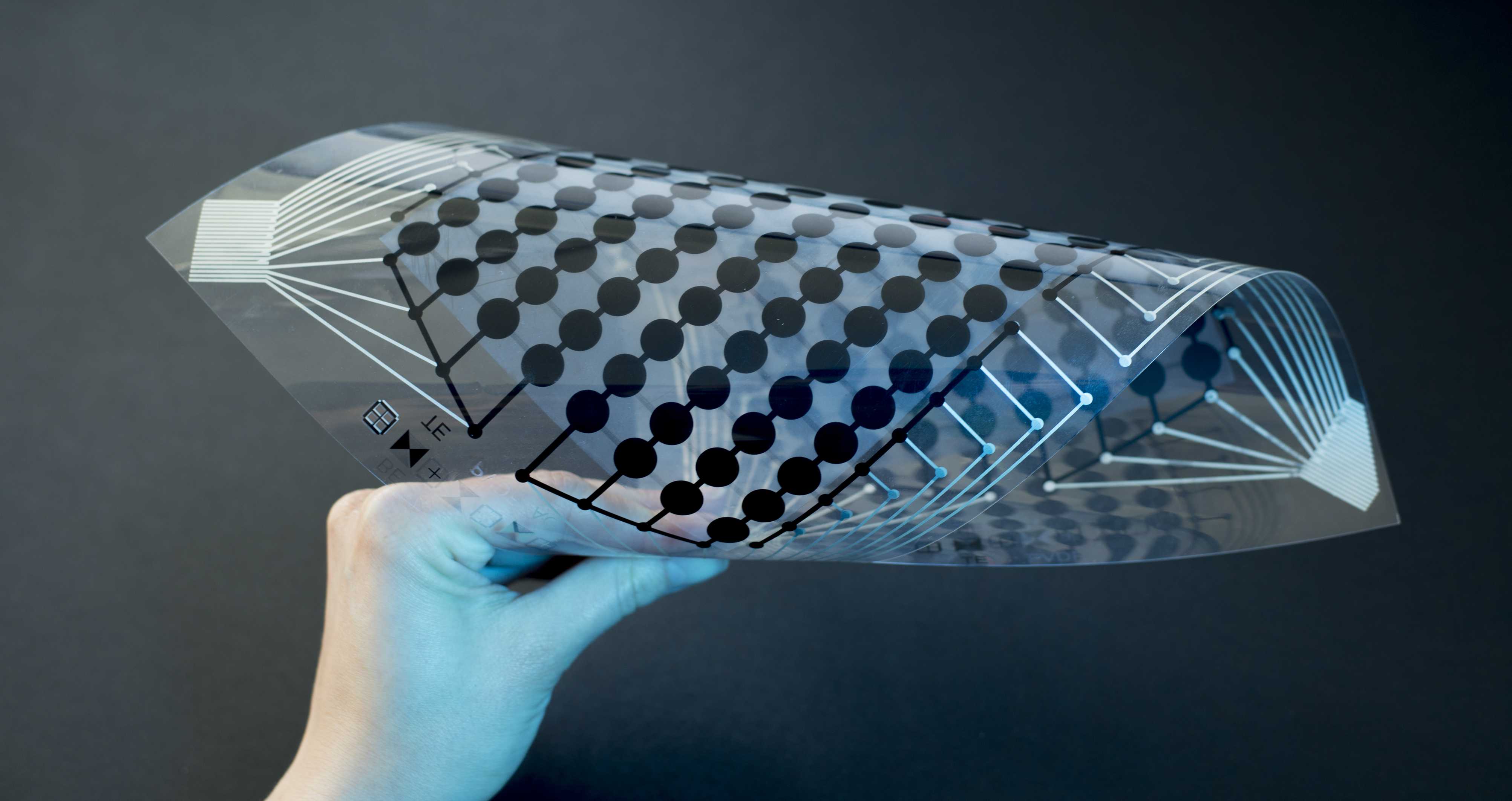

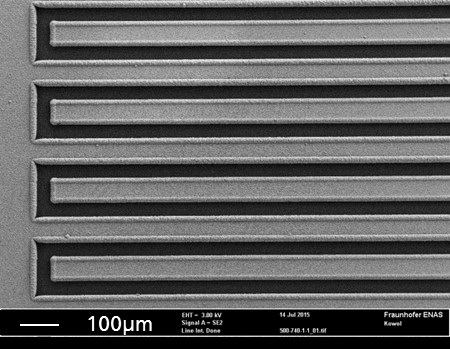

Fraunhofer IKTS presents screen-print pastes with a broad variety in properties for AlN and Si3N4 substrates. Screen-print thick-film technology offers a series of advantages in the design of electronic circuits: direct printing of high-performance resistors and conductors, embedding of single and power tracks, suitable for high-voltage- and high-frequency applications, realization of multilayer circuits, double-sided and any-shape usage. A growing number of customers stands for the quality of IKTS products.

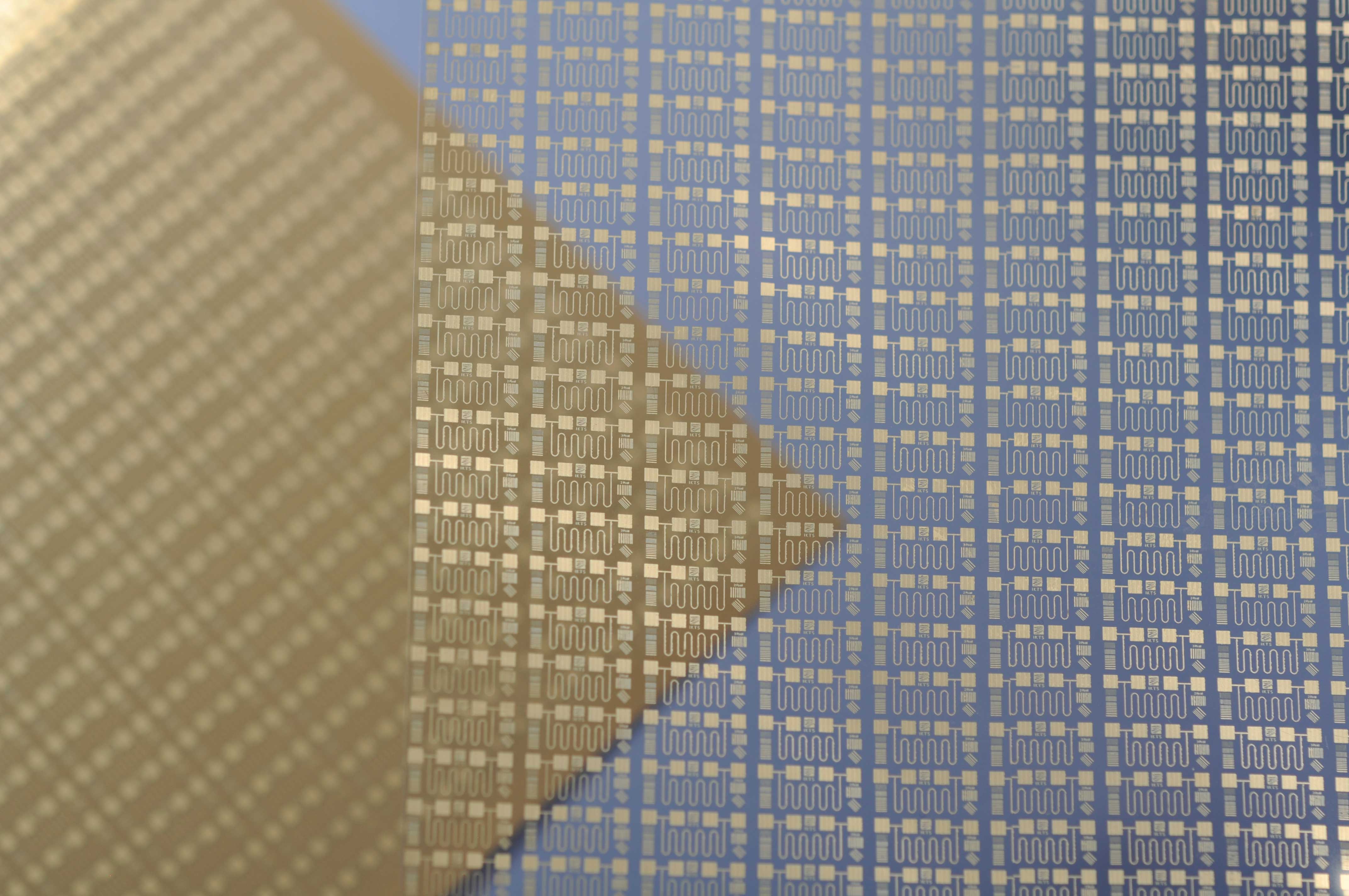

The Low Temperature Co-fired Ceramics (LTCC) multilayer technology has been a technology driver in microelectronic packaging since two decades. However, due to a limited chemical match between LTCC tape and the metallization, co-firing was often accompanied by undesired warpage effects and expensive post-firing processes had to be applied. IKTS researchers developed a series of new pastes especially dedicated to the co-firing process. The pastes match the sintering shrinkage of the tape precisely and enable low-cost sintering of highly integrated LTCC controller and sensor modules.

Nanoparticle-based metal inks

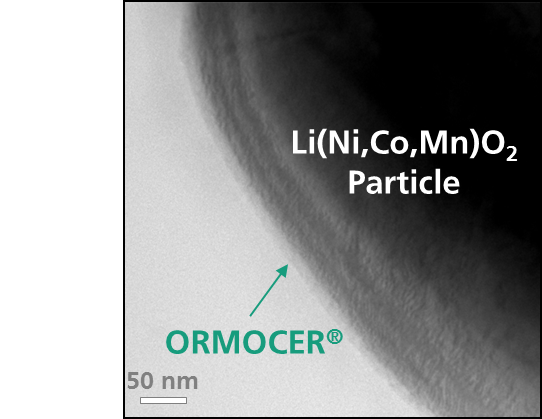

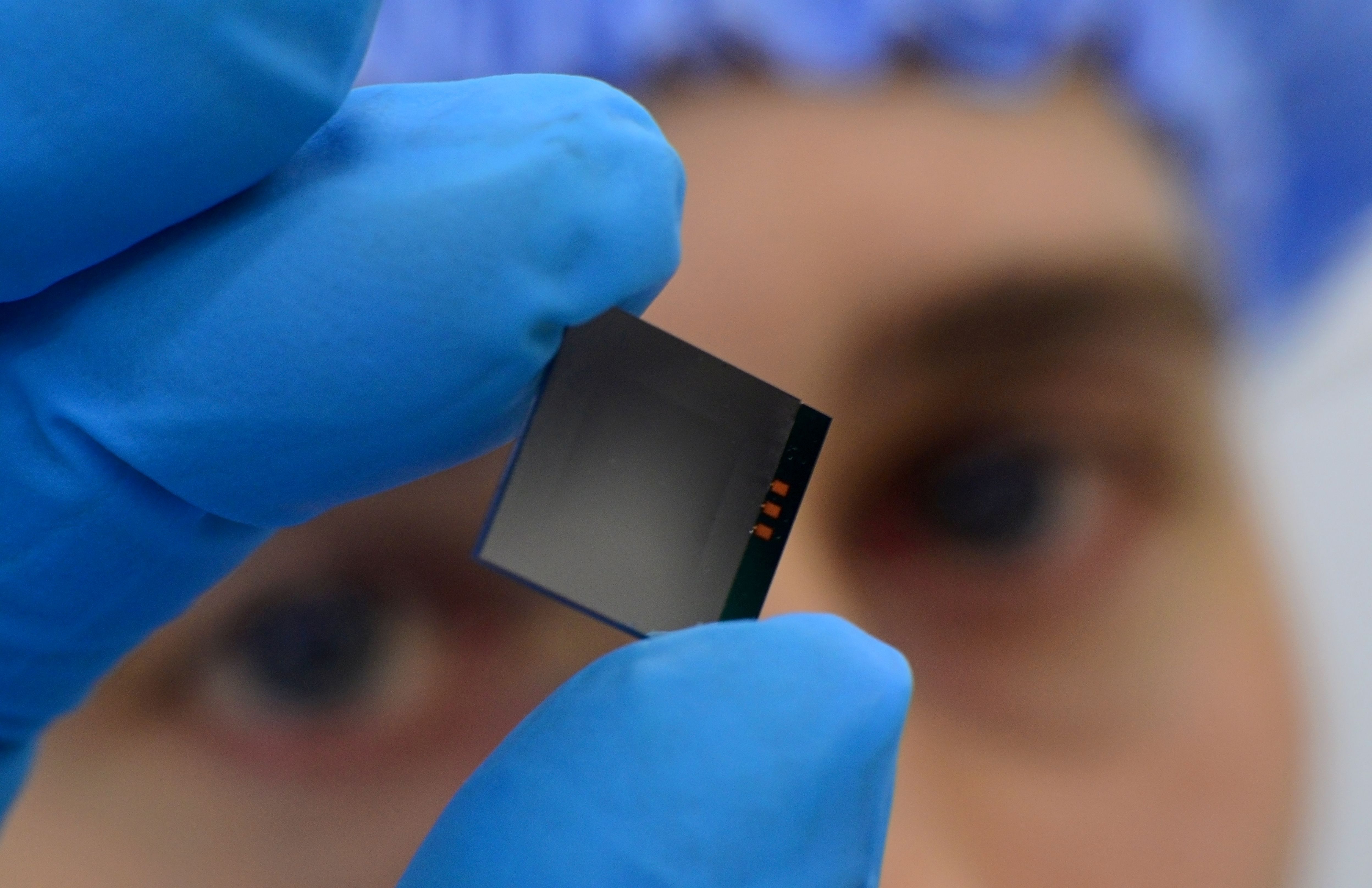

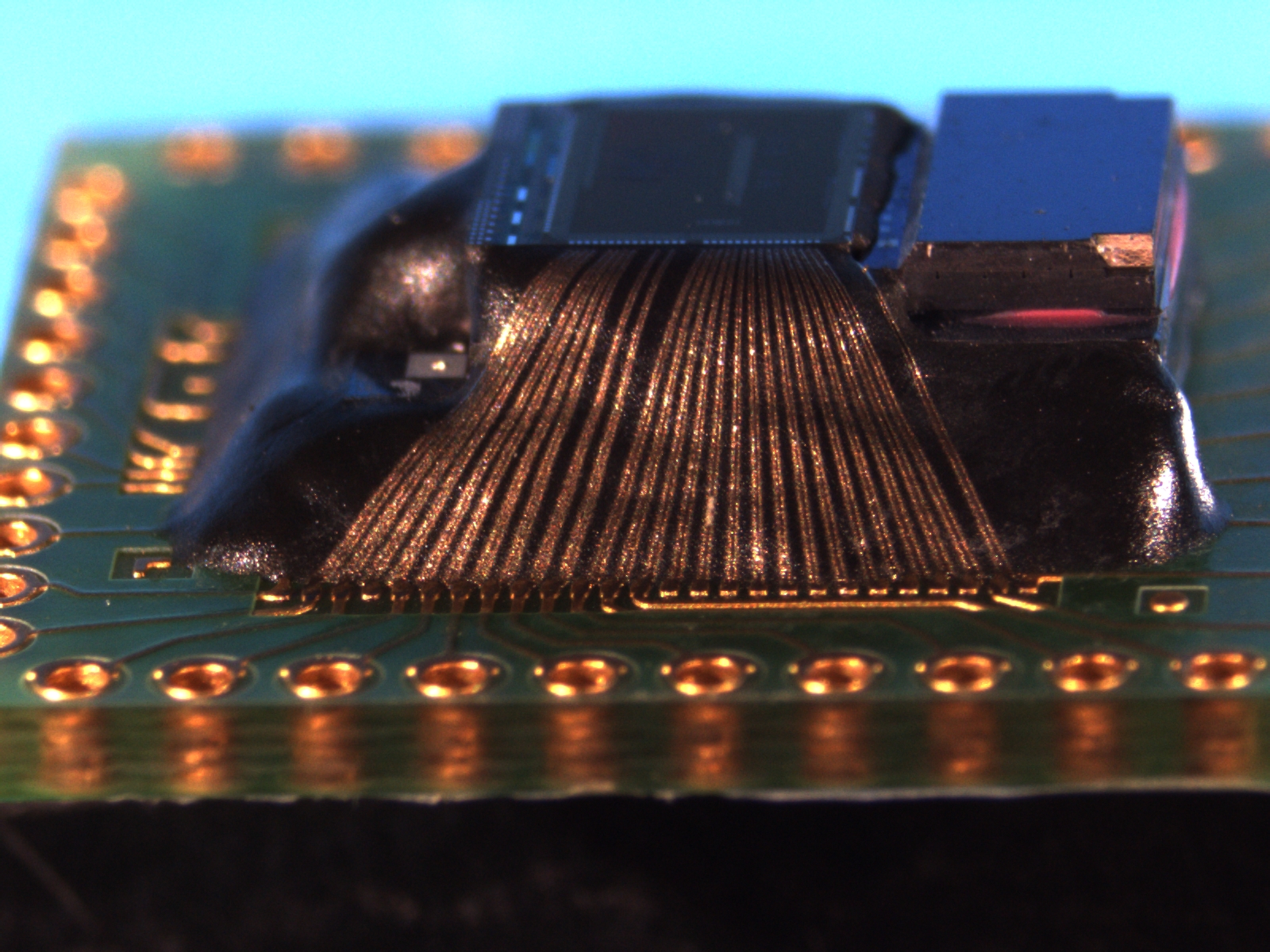

Based on experience with mixed oxides (perovskites, spinels, fluorites), noble metals and carbon-based materials different types of novel water-based metal nanoparticle (Ag, Au, Pt, Cu) printing inks, mixed oxides and slurries were developed, that are used in electrochemical storage and conversion devices as well as microsystems. All developed products have been adjusted for proper coating technologies like tape casting or direct writing methods. Extensive experience and outstanding technical equipment allow to satisfy the complex requirements in applications such as fuel cells, Li-ion batteries and supercapacitors as well as chemical and physical sensors.

For nanoinks the influence of different parameters (pH, concentration of metal, temperature and nature of a surfactant) on particle size distribution, viscosity and yield were investigated. The optimization of manufacturing steps with focus on volume manufacturing processes (up-scaling for powders, paste and inks production, applications for screen and ink-jet printing, cost effective co-sintering or low-temperature sintering etc.), reproducibility and cost reduction is an important factor for actual and further developments. With the help of the developed materials electronic components like antenna, heater and thermocouples as well as more complex components such as electrochemical cells, high-temperature fuel cell stacks, sensors, battery and capacitor electrodes are built up and qualified for system integration.

Fraunhofer Representative Office Japan

Fraunhofer Representative Office Japan