The 14th International Nanotechnology Exhibition & Conference (nano tech 2015)

Date&Time: January 28th - 30th, 2015, 10:00-17:00

Venue: Tokyo Big Sight, East Halls 4-6 & Conference Tower

----------------------------------------------------------------------------------------------------------

Researchers of Fraunhofer Institutes will have booths at nano tech 2015.

The following Fraunhofer Institutes will exhibit their latest developments:

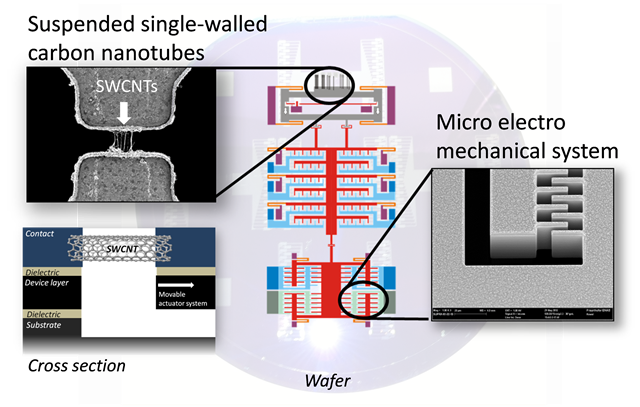

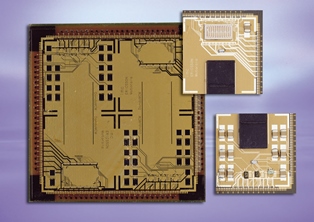

- Fraunhofer ENAS: Booth No. 5L-20

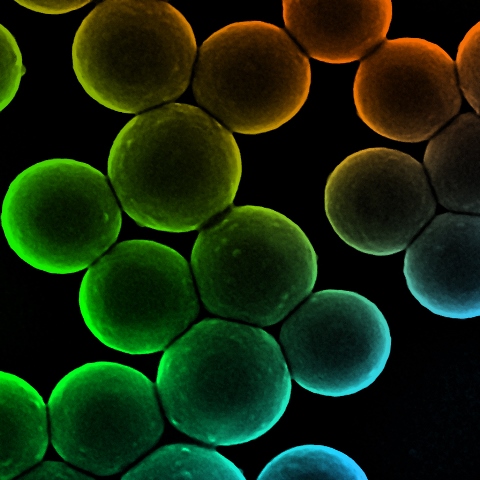

- Fraunhofer IKTS: Booth No. 5N-18

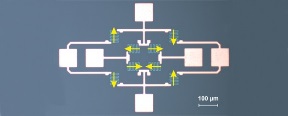

- Fraunhofer IMM: Booth No. 5J-02 (IVAM Booth)

- Fraunhofer ISC: Booth No. 5N-17

- Fraunhofer IWS: Booth No. 5Q-20 (Nanotech Kompetenz Zentrum Booth)

The detailed exhibition contents of each Fraunhofer Institutes, please see below.

------------------------------------

In addition to the booth exhibition, Fraunhofer researchers will give talks at the "Main Theater Presentation" on Jan.29th.

"Main Theater Presentation - German Pavilion Nanotechnology ~ Made in Germany"

Date&Time: 2015.01.29. (Thu), 10:20-12:20, 13:00-16:45

Venue: Main Theater (East Hall 5)

11:45-12:00

"Applications of next generation nano-materials based on sol-gel processing and nano-/microtechnology“

Dr. Michael Popall (Fraunhofer ISC)

13:15-13:35

"Use of alumina nano-powders for schrinkage control in silver powder firing"

Dr. Markus Eberstein (Fraunhofer IKTS)

13:35-13:55

"Ressource efficient innovations based on nano technologies"

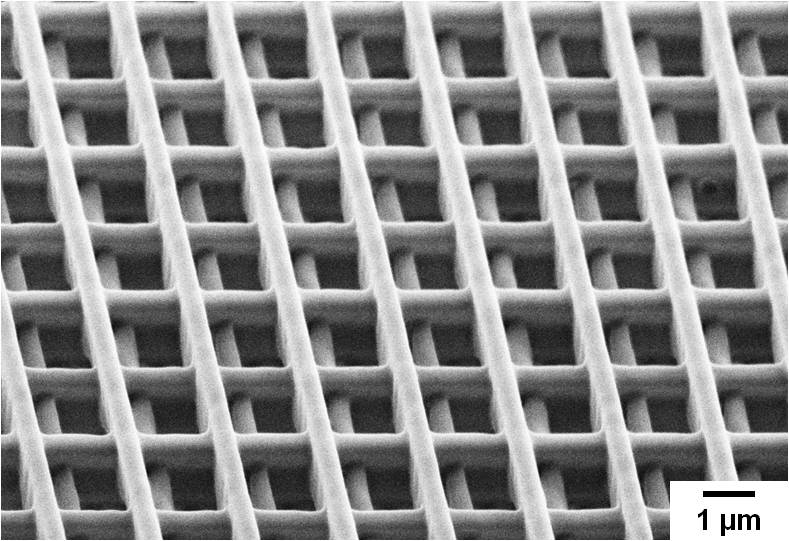

Prof. Dr. Thomas Geßner (Fraunhofer ENAS)

13:55-14:15

"Superhard carbon coatings for an improved energy efficiency"

Prof. Andreas Leson (Fraunhofer IWS)

14:15-14:35

"Nanostructured materials and processing techniques for Lithium Sulfur Batteries"

Prof. Stefan Kaskel (Fraunhofer IWS)

15:00-15:20

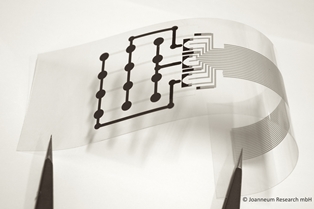

"Innovative 2D GMR sensors in monolithic integration for high-sensitivity applications"

Maria Almeida (Fraunhofer ENAS)

15:40-16:00

"Metal nano-inks for inkjet and aerosol printing"

Dr. Nikolai Trofimenko (Fraunhofer IKTS)

Fraunhofer Representative Office Japan

Fraunhofer Representative Office Japan