nano tech 2017

Date&Time: February 15-17, 2017, 10:00-17:00

Venue: Tokyo Big Sight, East 4・5・6 Hall & Conference Tower

Entrance Fee: 3,000 Japanese Yen(Free admission with online registration)

--------------------------------------------------------------------------------------------------------

Following institutes are going to introduce their latest research results:

Fraunhofer Institute for Ceramic Technologies and Systems IKTS: 5J-14

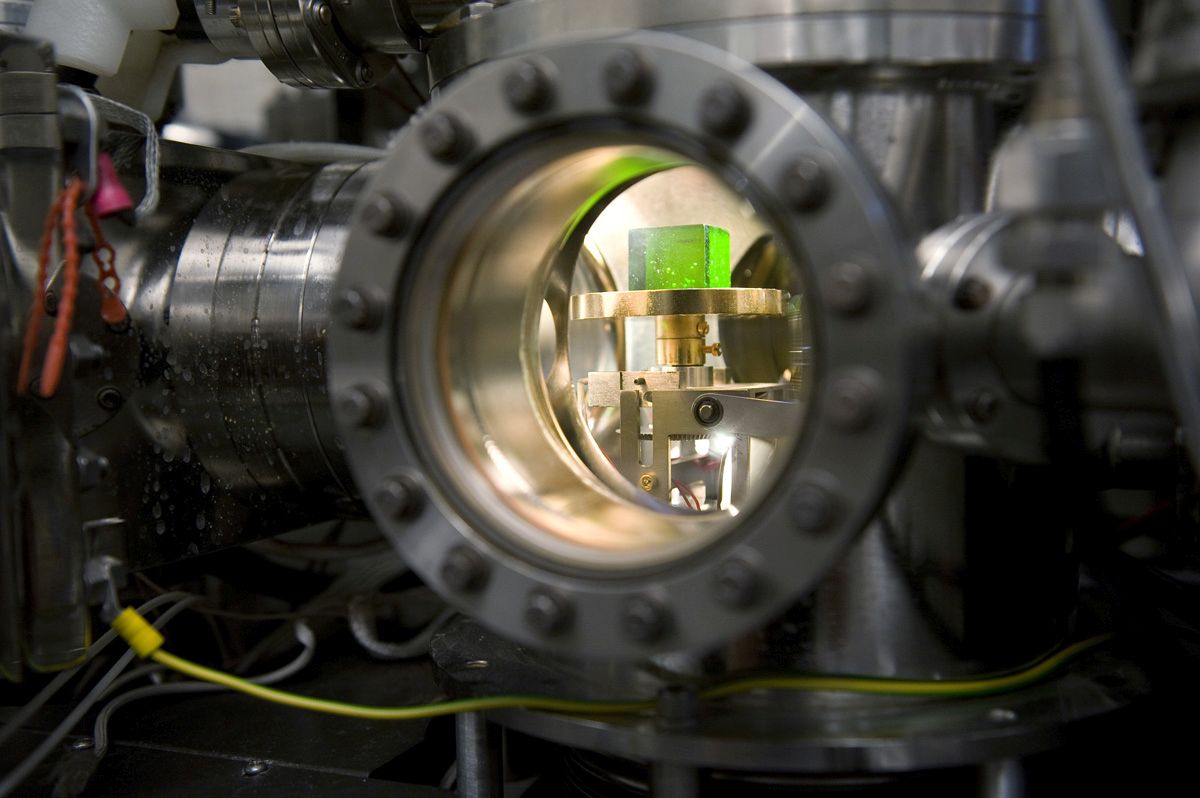

Fraunhofer Institute for Material and Beam Technology IWS: 5J-14

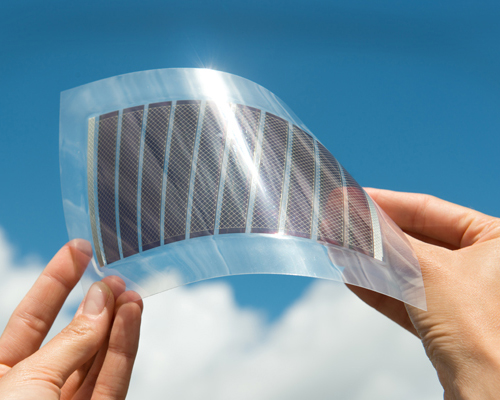

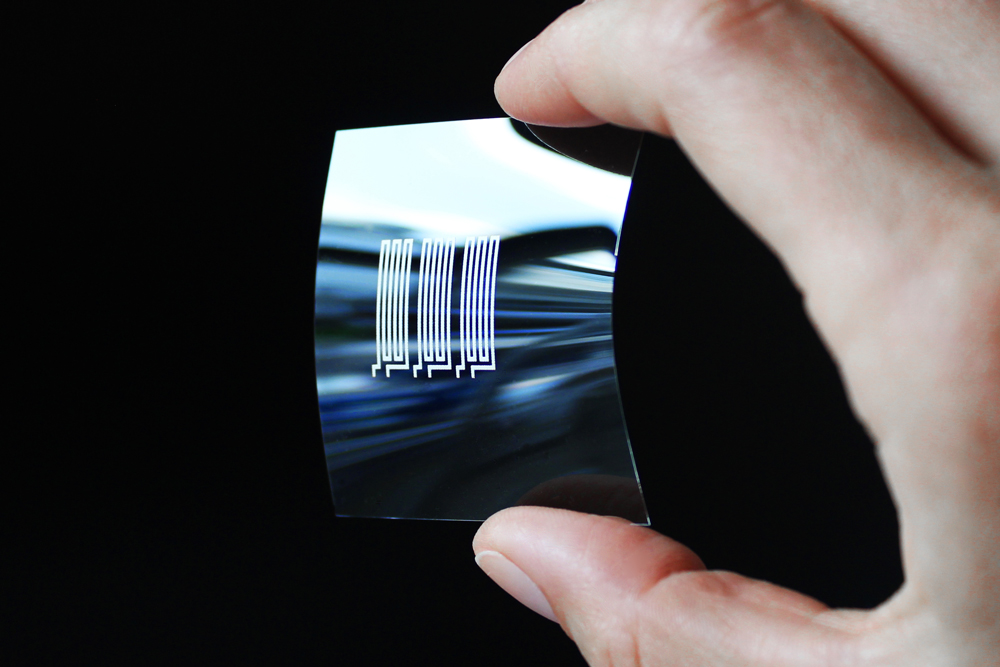

Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology FEP: 5J-14

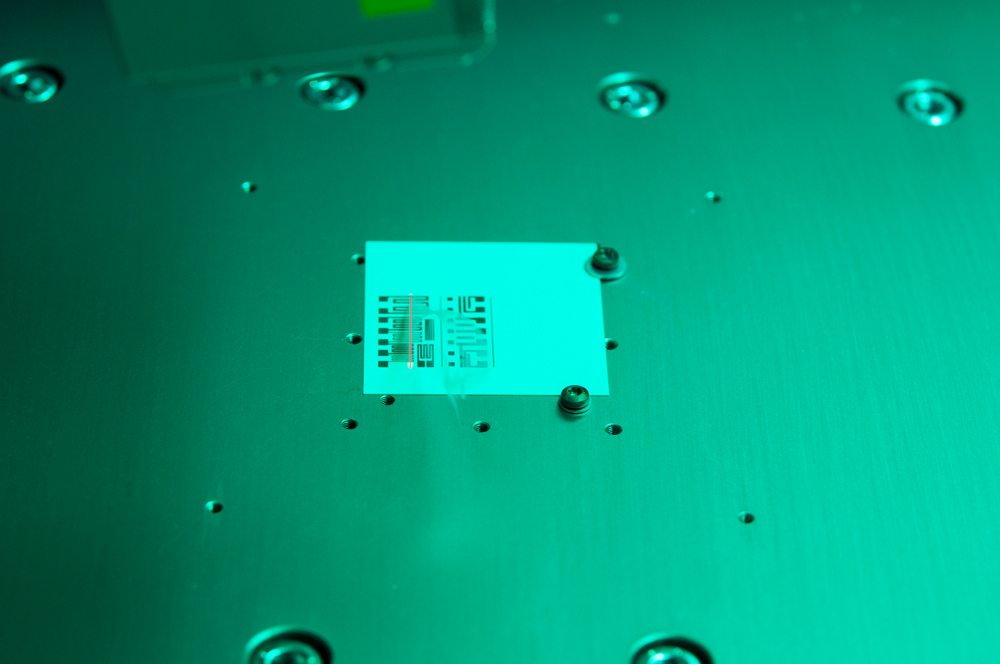

Fraunhofer Institute for for Reliability and Microintegration IZM-ASSID: 5J-14

Fraunhofer Institute for Silicate Research ISC: 5R-18

Fraunhofer Representative Office Japan

Fraunhofer Representative Office Japan